Description

AxiWeld Exothermic welding is a simple, cost effective, self contained and portable process of forming high quality and permanent metal-to-metal connections.

The AxiWeld line of products are manufactured and tested in accordance to IEEE 837.

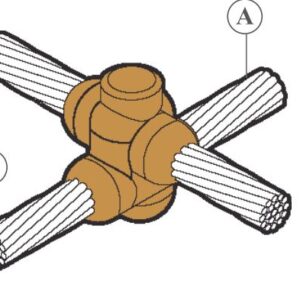

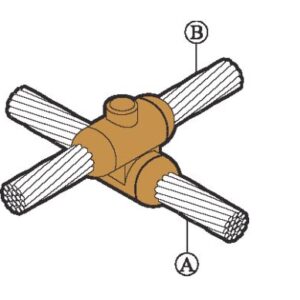

Through this process, connections are made by a reaction of a powdered copper compound and aluminium which allows superheated molten copper alloy to form on and around the conductors to be joined. The final connections are electrically conductive due to their high copper content and have strong corrosion resistant properties.

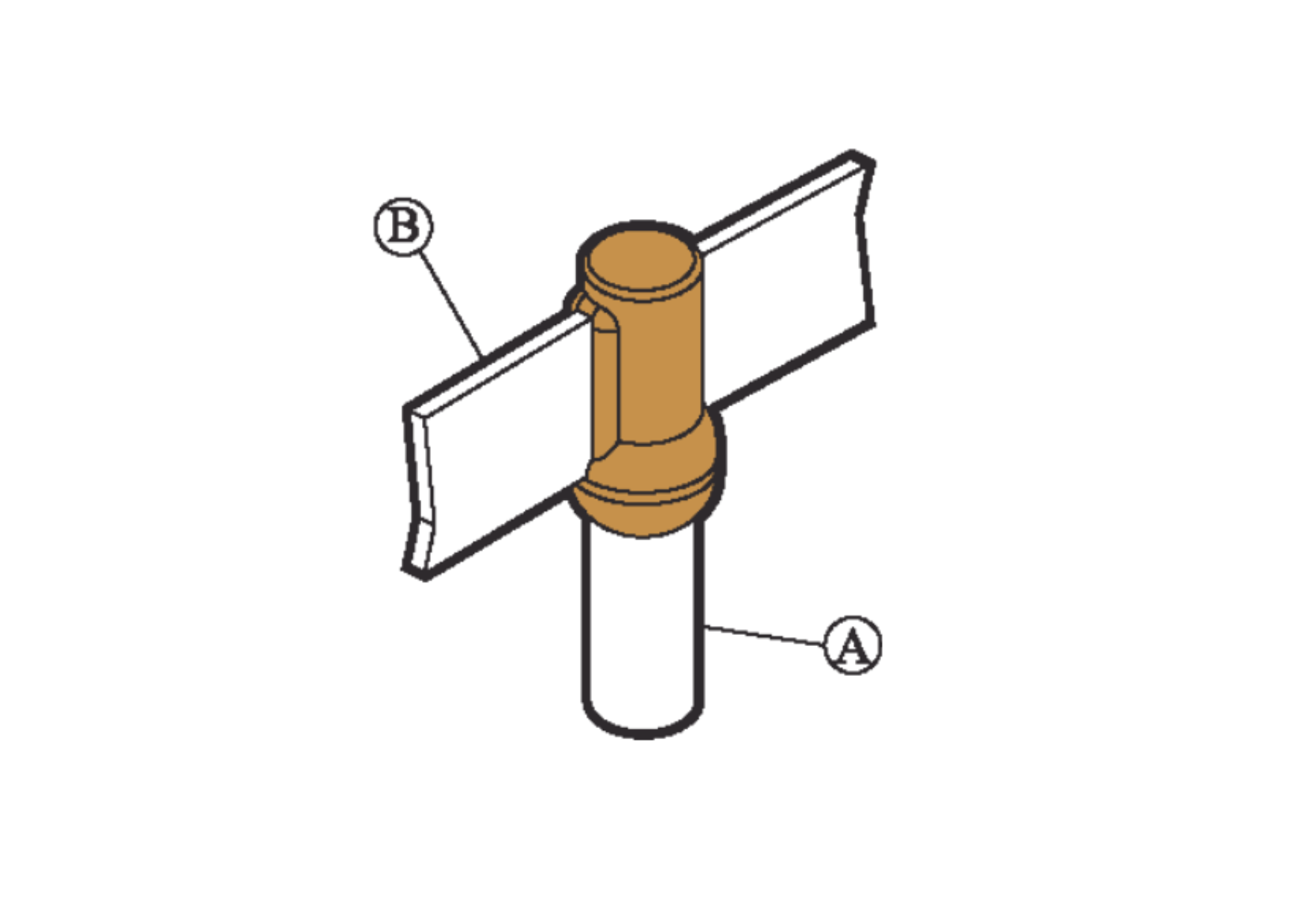

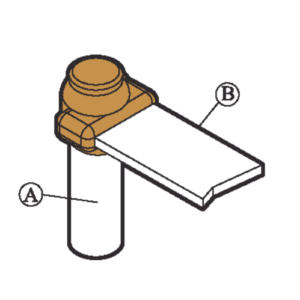

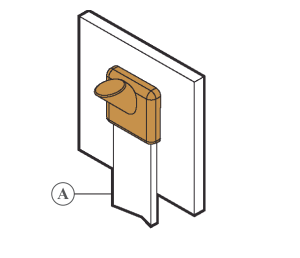

The exothermic welding process can be used to weld materials for electrical purposes including but not limited to:

Stainless Steel, Brass, Copper, Bronze, Galvanized Steel, Steel Rail, Cast Iron and Copper Clad Steel.

Application :

AxiWeld Exothermic welding is a simple, cost effective, self contained and portable process of forming high quality and permanent metal-to-metal connections.

The AxiWeld line of products are manufactured and tested in accordance to IEEE 837.

Through this process, connections are made by a reaction of a powdered copper compound and aluminium which allows superheated molten copper alloy to form on and around the conductors to be joined. The final connections are electrically conductive due to their high copper content and have strong corrosion resistant properties.

The exothermic welding process can be used to weld materials for electrical purposes including but not limited to:

Stainless Steel, Brass, Copper, Bronze, Galvanized Steel, Steel Rail, Cast Iron and Copper Clad Steel.

Installation :

The majority of connections have at least twice the cross sectional area of the conductors being joined and equivalent or greater current carrying capacity because the connection is a fusion of high conductivity high copper content alloy it will withstand repeated fault current and will not loosen in the way that mechanical connectors can corrosion resistance too, is exceptional, due to the alloy very high copper content.

The moulds are designed to complete 30-40 connections depending on the care given to the mould during usage, transport and storage.