Description

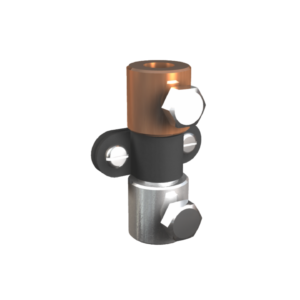

The Earth Boss is designed to provide an earth connection point on a steel structure. It is a metal fitting or connector that is used to connect a conductor, such as a wire or rod, to a metal surface or structure. It is welded onto steel vessels, tanks and other structures and is used as part of an earthing or grounding system. The resulting weld is wrapped with Denso Tape to prevent moisture ingress.

Axis Earth boss is manufactured from high tensile mild steel, zinc plated to avoid corrosion & supplied with studs & bolts made of steel with spring & plain washer. They are designed to provide a low-resistance connection to the earth.

Earth bosses are used for equipotential bonding, which is the process of connecting different metal parts or structures together in such a way that they are at the same electrical potential. This helps to prevent potential differences between these parts or structures, which can cause electrical shocks or other hazards. They are an important component of electrical safety systems and are commonly used in a variety of applications, including residential, commercial, and industrial settings.

| Length (mm) |

Dia (mm) |

Thread Dia Inch |

Code |

| 25 |

20 |

3/8 |

EB2025 |

| 25 |

25 |

3/8 |

EB2525 |

| 38 |

30 |

3/8 |

EB3038 |

| 40 |

40 |

1/2 |

EB4040 |

| 50 |

50 |

1/2 |

EB5050 |

NOTE : OTHER SIZES & COMBINATIONS AVAILABLE ALSO AVAILABLE IN STAINLESS STEEL

CABLE LUG IS NOT A PART OF THE EARTH BOSS

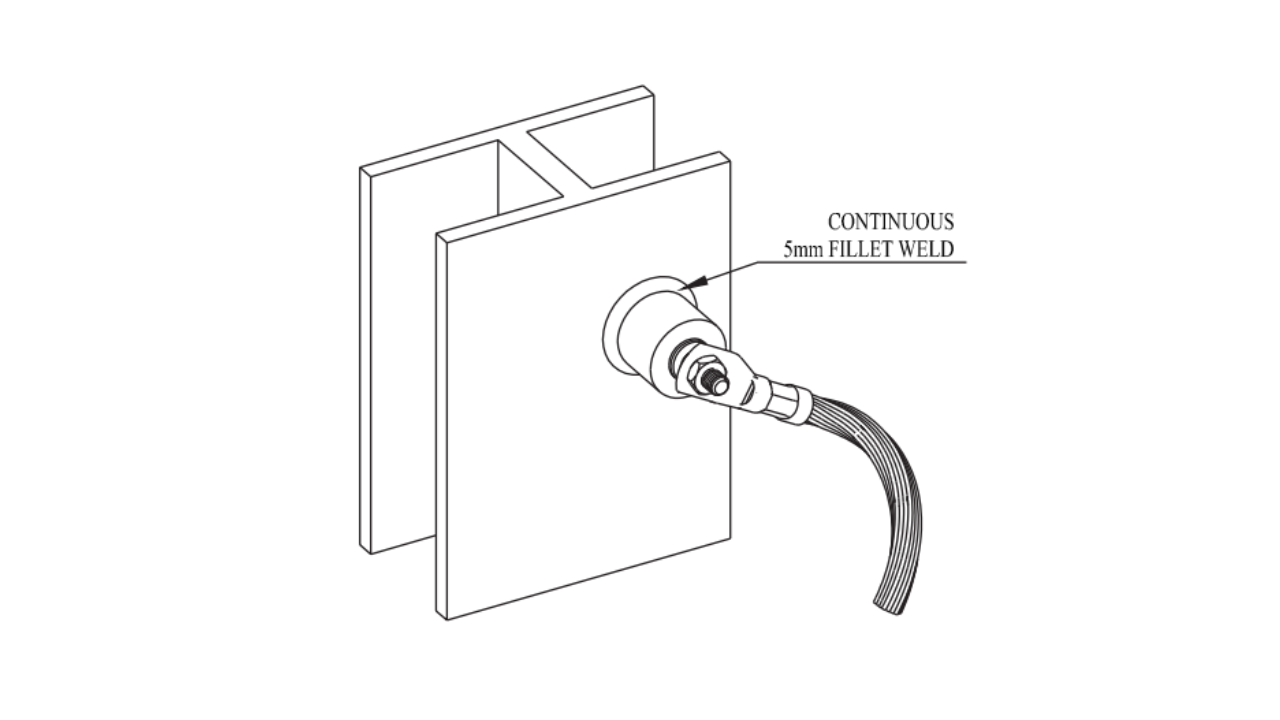

Welding an earth boss onto a steel structure is a process that requires proper preparation, equipment, and safety precautions. Here are the steps you can follow to weld an earth boss onto a steel structure:

- Gather the necessary equipment: In addition to the earth boss, you will need a welding machine, electrodes, a wire brush, and personal protective equipment such as a welding helmet, gloves, and protective clothing.

- Prepare the steel structure: Clean the area where the earth boss will be attached using a wire brush to remove any dirt, rust, or debris. This will help ensure a b and secure weld.

- Position the earth boss: Place the earth boss in the desired location on the steel structure and mark the attachment points with a pencil or marker.

- Set up the welding machine: Follow the manufacturer’s instructions to set up the welding machine and select the appropriate electrodes for the type of steel you are working with.

- Weld the earth boss: Put on your protective equipment and start the welding machine. Hold the electrode at a 45-degree angle to the steel and make a series of short, overlapping welds. Be sure to maintain the correct distance between the electrode and the steel to ensure a b and consistent weld.

- Finish the weld: Once the earth boss is securely attached, use a wire brush to remove any excess slag or debris from the weld.